MICRO FACTORIES

Image AI generated with Gemini

005

Manufacturing has pivotal moments of innovation that define new eras of production. Today, we are transitioning into Industry 4.0, characterized by Artificial intelligence, internet of things, rapid manufacturing techniques, and robotics. What Industry 4.0 also enables is a shift in the scale of production, from Giga factories to their smaller counterparts, the micro factory.

Intro

Microfactories are small to medium-sized production facilities that challenge the model of traditional assembly lines and larger factories. A concept developed in the 1990s that puts a focus on node-based manufacturing and automation, these factories are small, agile, and scalable. Progressing a handful of decades since its inception, manufacturing techniques and computing power have positioned microfactories as a competitive solution used in the auto, consumer product, and construction industries.

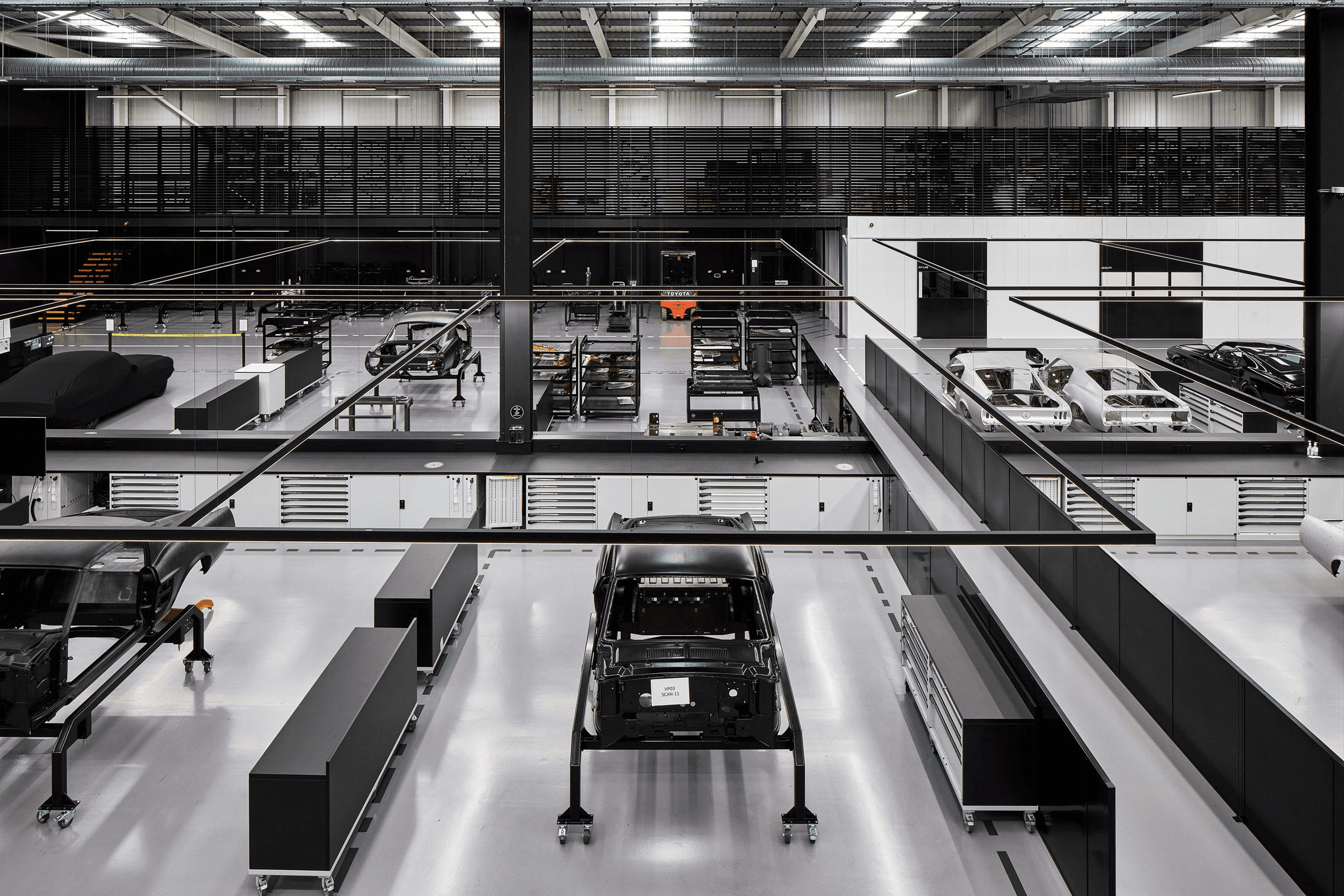

An assembly line factory on the left

compared to Charge Cars micro factory on the right

To better understand their value, we can compare their structure to that of a traditional factory with an assembly line model. Assembly line manufacturing is a linear process with products moving in a sequential order. Products stop at predefined stations where a specific task is performed, then move on to the next station. An assembly line production's strength is in its scale, the standardization of its parts, and its continuous flow of goods with consistent outputs.

Microfactories fundamentally differ in that approach, favoring a node-based system. Instead of products moving through one continuous line, a single workstation at a time, they move through nodes. Each node, or cell, has the capability to perform multiple tasks in the production process. Additionally, nodes can be rapidly reconfigured for new production processes. Linking multiple nodes together allows for a more flexible and agile production process with the capability to scale, matching market demands.

Image AI generated with Gemini

Technology

But key to microfactories' success might be the technologies that enable them. It's easiest to break this into two buckets: manufacturing techniques and their support systems. Manufacturing techniques include additive manufacturing (3D Printing), CNC machining, laser cutting, and printed electronics, or any manufacturing platform that offers flexibility and modularity in its process. 3D printing and CNC machining can create complex geometries with precision and in a variety of materials. Their flexibility and innate process also cut down on traditional tooling costs and setup times, reducing tool downtime. Printed electronics is an emerging platform for manufacturing circuit boards. In the second bucket, we have the Internet of Things (IoT), robotics, and AI that connect nodes and their manufacturing techniques. IoT enables the connectivity of unique machinery, supplying relevant data to the network. Using this data, AI and machine learning can optimize tasks, provide quality control, and reduce material waste. Physically connecting parts to processes, robotic platforms transport and handle material and perform repetitive tasks. Key to these processes and systems is their flexibility and ability to be rapidly reconfigured.

So why does this matter for companies? Microfactories offer unique advantages, providing speed to market, innovative business models, and localized solutions. Cuby uses microfactories to dramatically reduce the cost of home construction.Hadrian has adopted a "factory-for-hire" model, providing flexible, specialized manufacturing solutions for the defense sector. Lastly, Unspun uses 3D weaving to create on-demand apparel. All of these are based on a microfactory model in their industry niche.

In Part 2, we’ll look at how to set up a microfactory on a community scale and how we at the Water Boys envisioned one for a Water Boys service.

ISSUE 001

Researched by: Its The WaterBoys

Author: Nick Barnette